Fast, reliable fulfillment now depends on how well you handle items not pallets. That’s why more operations are moving from manual stations to an automated piece picking lane anchored by a robotic piece picking system. When designed correctly, this lane converts chaotic totes into a steady pick-to-pack rhythm that holds up during peaks and labor gaps.

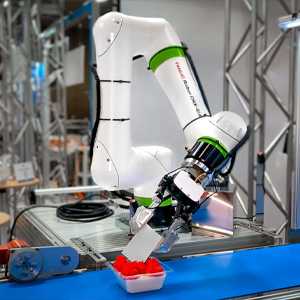

How the cell actually works

At the center is an AI picking robot that identifies each product, chooses a stable grasp, and executes a precise transfer. In most layouts, the arm serves as a pick and place robot, handing the item to a chute, carton, or packaging throat. Pairing the cell with robotic bagging unlocks direct-to-bag fulfillment: pick → drop → seal → label → sortation. Fewer touchpoints shorten cycle time and deliver a consistent presentation at weigh/scan.

Why it matters for operations

Good warehouse automation picking is less about headline peak numbers and more about consistency you can plan around. Vision-confirmed picks reduce mispicks and reships. Standardized handoffs keep pack stations balanced. When volumes spike or staffing dips, a stable automated lane protects promise dates without adding floor space.

What to validate before you buy

Real performance depends on your SKUs and presentation. Run a focused pilot on your floor and measure what counts:

- SKU coverage & accuracy: Include rigid boxes, poly mailers, glossy films, and clear clamshells. Track first-pass pick success and exception rates over multi-hour runs.

- Sustained throughput: Validate average picks per hour under your lighting and tote pitch; peaks alone can mislead.

- Integration depth: Confirm clean handshakes with WMS/WES, scanners, scales, and the bagger so confirmations and labels post automatically.

- Changeover & learning: New SKUs should take minutes, not days. Favor systems that improve grasp strategies over time.

- Uptime & service: MTBF/MTTR, spares availability, and response commitments protect day-two performance.

Handling real-world variation

Real warehouses are messy. Robot piece picking has to cope with mixed orientations, reflective packaging, and soft goods. Modern cells combine depth sensing, grasp libraries, and confidence checks so a warehouse picking robot can keep flow steady even in “random” presentation. That steadiness is where the ROI appears.

Choosing platforms with data not hype

It’s common to see comparison threads like piecepicking vs osaro when shortlisting vendors. Treat them as a cue to run side-by-side trials using your SKUs, identical fixtures, and a neutral scorecard: coverage, sustained PPH, exception recovery, integration effort, and support quality. The best platform is the one your operators trust on a peak Monday afternoon.

Packaging that matches the picker

If your orders skew single-line, connect picking directly to packaging. With robotic bagging, items move from the pick and place robot into the bagger for seal, print, and verification true direct-to-bag fulfillment. The result is fewer manual touches, cleaner labels, and faster induction to carrier sortation.

A well-implemented robotic piece picking system driven by an AI picking robot, orchestrated as pick and place, and finished with robotic bagging turns Piece Picking into a dependable engine. Validate with real data, compare vendors on equal ground, and scale what works. That’s how warehouse automation picking becomes faster cycles, fewer errors, and promises kept day after day.